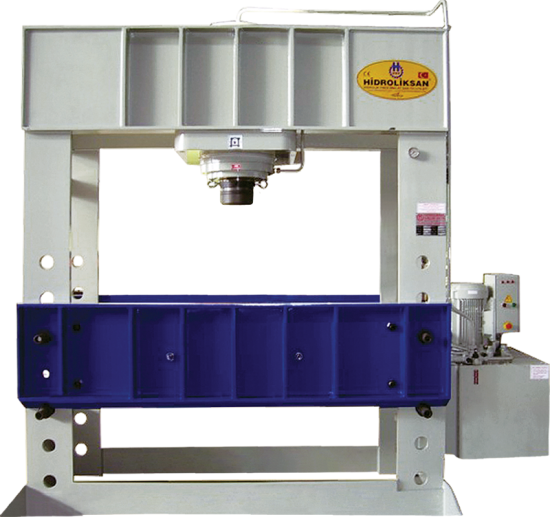

CUSTOM DESIGN

In addition to offering standard products in different tones and capacities to customers, WSP can also produce presses specially designed to meet customer needs. There may be several reasons why special presses are required. Some of these reasons are as follows:

WHY WOULD YOU NEED CUSTOM DESIGN WORKSHOP PRESS?

- Area constraint

- Capacity requirement

- Product features to be processed

- Different mold requirements

- Working speed change